AC synchronous machines

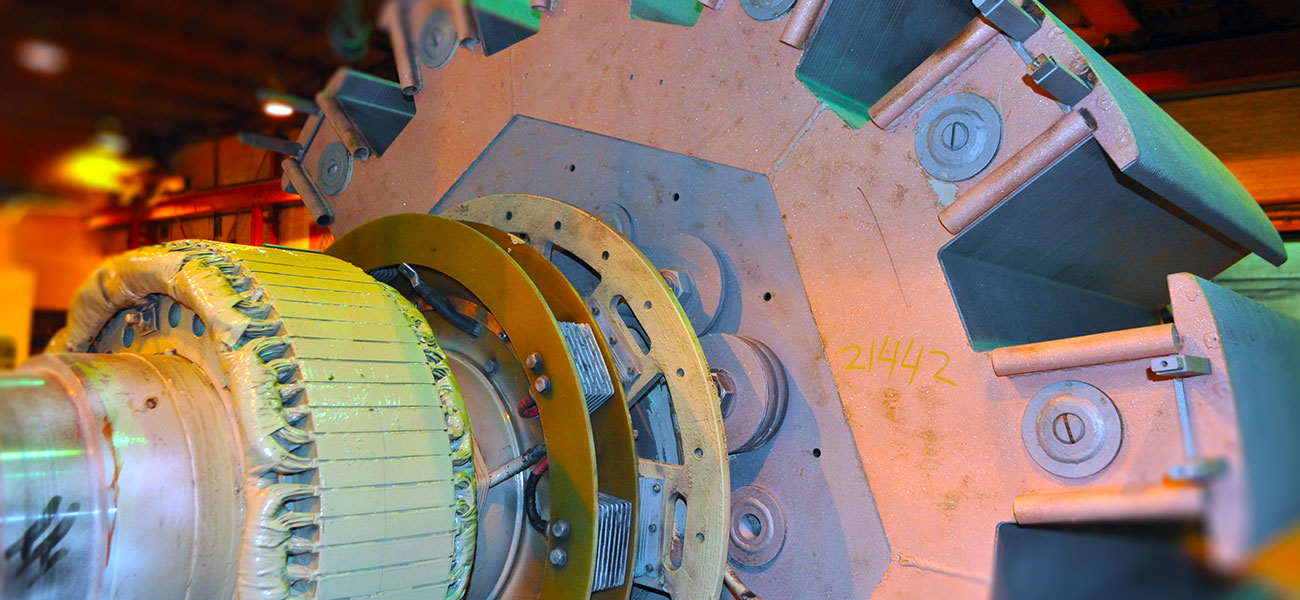

Salient pole rotor

Salient pole rotors and generators are typically used either in lower speed electrical applications such as hydro power plants or high speed applications such as refiners and compressors. The rotors of such machines will have between 4 and 60 field poles. Over the years, Motion Electric Motor Services has developed a unique approach to the refurbishment of such machines. The scope of work can include:

- Dismantling of salient poles from the rotor (on site or in-shop)

- Removal of the insulation (safe asbestos abatement through a unique patented chemical bath). Original Shape, dielectric and mechanical properties of cupper & poles maintained & guaranteed.

- Core insulation

- Coil winding

- Coil insulation

- Bonding under constant heat and pressure

- Electrical testing throughout the refurbishment process & final tests

- Retrofit available for GE and ABB/ASEA design to prevent premature failure

Integral solid pole rotor

Some manufacturers use an integral solid pole rotor design to provide maximum strength and stiffness and to increase the useful life of the unit. Every turn has mechanical locks and brazed corner joints. These units will typically have 4 to 6 poles.

Motion Electric has invested in custom-made equipment to wind these large size solid & integral poles with strip-on-edge field winding. We guarantee performance that is at least the same or better than the original.

Turbo-generators

Turbo-generators are used in high-speed applications such as steam turbine generators and gas and diesel engine generators. The two field windings are completely embedded and wedged into slots in the rotor surface, forming a spiral around each pole center. Motion Electric has the in-shop expertise to perform the delicate rewinding procedure:

- Dismantling of the poles from the turbo-generator rotor

- Removal of the insulation (safe asbestos abatement through chemical bath)

- Core insulation

- Coil insulation

- Removal/replacement of retaining rings

- High-speed dynamic balancing, including over speed run.

- Electrical testing throughout the refurbishment process & final tests

- Exciter retro-fit (see hydro section)

AC synchronous machines specialty services

STATOR

- Coil manufacturing

- Stator restacking

- Stator rewind

- B-stage coil manufacturing

- B-Stage with VPI combined coil manufacturing

- Safe asbestos abatement

- Dove tail repair

- 16-ft diameter VPI tank

AVAILABLES TESTS AND RELIABILITY AUDIT

- Core loss test

- Infrared inspection

- Stator hot spots test

- ELCID test

- Partial discharge

- Slow roll test (electrical run-outs)

- Single-phased rotor test

- Roundness check

- Turn-to-turn insulation test

- AC drop volt test

- Winding resistance

- Insulation resistance

- Megger

- Polarization Index (PI)

- Dielectric Discharge Test (DDT)

- Laser alignment

- Vibration analysis